Page 36 - ameft-journal-2022-1

P. 36

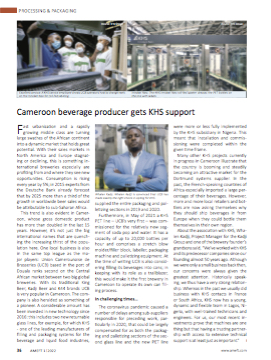

Excellent service: A KHS service employee shows UCB operators how to change reels Innoket Neo: The KHS Innoket Neo roll-fed labeler dresses the PET bottles on on the Innoket Neo for roll-fed labeling. the line with labels.

PROCESSING & PACKAGING

Fast urbanization and a rapidly growing middle class are turning large swathes of the African continent into a dynamic market that holds great potential. With their sales markets in North America and Europe stagnat- ing or declining, this is something in- ternational breweries especially are profiting from and where they see new opportunities. Consumption is rising every year by 5%; in 2015 experts from the Deutsche Bank already forecast that by 2025 more than a third of the growth in worldwide beer sales would be attributable to sub-Saharan Africa.

This trend is also evident in Camer- oon, whose gross domestic product has more than doubled in the last 15 years. However, it’s not just the big international names that are quench- ing the increasing thirst of the popu- lation here. One local business is also in the same top league as the ma- jor players: Union Camerounaise de Brasseries (UCB) based in the port of Douala ranks second on the Central African market between two big global breweries. With its traditional King Beer, Kadji Beer and K44 brands UCB is very popular in Cameroon. The com- pany is also heralded as something of a pioneer. A considerable amount has been invested in new technology since 2016: this includes two new returnable glass lines, for example, for which KHS - one of the leading manufacturers of filling and packaging systems for the beverage and liquid food industries,

36 AMEFT 1 2022

(Source: KHS Group)

were more or less fully implemented by the KHS subsidiary in Nigeria. This meant that installation and commis- sioning were completed within the given time frame.

Many other KHS projects currently in progress in Cameroon illustrate that the country is booming and steadily becoming an attractive market for the Dortmund systems supplier. In the past, the French-speaking countries of Africa especially imported a large per- centage of their beverages. However, more and more local retailers and bot- tlers are now asking themselves why they should ship beverages in from Europe when they could bottle them themselves in their own region.

About the association with KHS, Wha- len Kadji, Project Manager for the Kadji Group and one of the brewery founder’s grandsons said, “We’ve worked with KHS and its predecessor companies since our founding almost 50 years ago. Although we were only a small business back then, our concerns were always given the greatest attention. Historically speak- ing, we thus have a very strong relation- ship. Whereas in the past we usually did business with KHS contacts in France or South Africa, KHS now has a young, dynamic and flexible team in Lagos, Ni- geria, with well-trained technicians and engineers. For us, our most recent in- vestments prove that machines are one thing but that having a trusting partner- ship with access to extensive technical support is at least just as important.”

(Source: KHS Group) (Source: KHS Group)

Cameroon beverage producer gets KHS support

Whalen Kadji: Whalen Kadji is convinced that UCB has made exactly the right choice in opting for KHS.

supplied the entire packaging and pal- letizing sections in 2019 and 2020.

Furthermore, in May of 2021 a KHS PET line – UCB’s very first – was com- missioned for the relatively new seg- ment of soda pop and water. It has a capacity of up to 20,000 bottles per hour and comprises a stretch blow molder/filler block, labeller, packaging machine and palletizing equipment. At the time of writing UCB is also consid- ering filling its beverages into cans; in keeping with its role as a trailblazer, this would make it the first brewery in Cameroon to operate its own can fill- ing process.

In challenging times...

The coronavirus pandemic caused a number of delays among sub-suppliers responsible for preceding work, par- ticularly in 2020, that could be largely compensated for as both the packag- ing and palletizing sections of the sec- ond glass line and the new PET line

www.ameft.com